- products: brazed | double wall brazed | shell and tube | shell & coil | pool heaters | air to water

- applications: radiant floor heating | snow melting systems | district heating

Brazed

Heat Exchangers

Brazed

Heat Exchangers

The brazed heat exchanger is the most advanced form of the compact plate heat exchanger especially designed for a wide range of applications in both process and hydronic applications. These heat exchangers are also widely used for refrigeration applications as evaporators, condensers and sub-coolers.

Operating

Principle

The brazed plate heat exchanger has a simple operating principle. Based

on the plate and nozzle orientation, each fluid passes through alternative

channels within the heat exchanger. All plate material and nozzles are

Stainless Steel 316 with 99.9% copper used for brazing the heat exchanger

together.

An extremely high heat transfer coefficient is attained due to the flow characteristics in each channel. A specially designed and tested chevron pattern causes a turbulent flow of the fluid resulting in higher heat transfer.

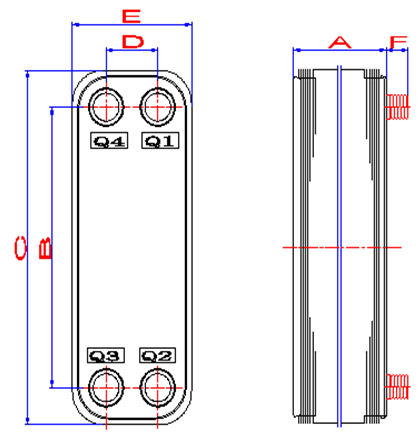

| - | A | B | C | D | E | F | Pressure | Temperature |

| - | inch | inch | inch | inch | inch | mm | psi | F |

| BPL24 | 0.27+0.09n | 6.14 | 7.72 | 1.81 | 3.39 | 12 | 450 | 428 |

| BPL60 | 0.35+0.10n | 9.56 | 11.26 | 2.84 | 4.57 | 24 | 450 | 428 |

| BPL200 | 0.43+0.11n | 20.43 | 24.25 | 3.62 | 7.52 | 48 | 450 | 437 |

Advantages

of the Brazed Heat Exchanger

Compact:

Due to the high efficiency of the brazed plate heat exchangers, these

heat exchangers are often half the size of conventional shell & tube heat

exchangers. The smaller footprint also makes it easier to be installed

on skid systems and portable equipment packages.

High

Efficiency:

Due to the turbulent flow of the fluid in the channels, the heat transfer

coefficients of our brazed plate heat exchangers are 3-5 times higher

than that of a conventional Shell & Tube heat exchanger for a similar

application.

Rugged

Construction:

The brazed plate heat exchanger is brazed using 99.9% copper. The copper

provides a strong bond when heated in a special furnace, keeping the plates

bonded together. The heat exchangers have a high pressure-temperature

rating. All our copper brazed heat exchangers are rated for 450 psig, 428

F degrees..

Closer

Approach

The brazed plate heat exchanger can provide a temperature approach of

1 degree F. This allows for maximum utilization of waste heat recovery.

24-Hour

Service:

We can be reached on a 24 hour basis, 7 days a week for any replacement

of heat exchangers on an emergency basis.

Stock:

We stock a complete range of brazed plate heat exchangers at our facility

to meet all your heat transfer requirements.

Please note that all our heat exchangers are available for immediate delivery.

Do you still have questions? We invite you to call or email us today for more information. We'll be happy to provide you with a heat exchanger that matches your specific needs.